|

||||||||||

|

|

K Series Tabbers

The KT and KT2 are similar tabbing modules. The main difference is in the added tabbing head on the KT2 allowing it to apply either 1 or 2 tabs.

Both units are known as crash tabbers in which the edge of the piece to be tabbed is fed into the machine first. That edge contacts the tab which has fed down in front of the piece, pulling the tab from its backing paper. The tab and the piece then crash into a sweep and roller system that folds the tab neatly and tightly to the piece.

Advantages of Crash Tabbers:

Advantages of Crash Tabbers:

- High productivity. The shortest dimension feeds through the machine increasing production rates at any given speed.

- Simplicity. Short paper path with no skewing adjustment etc.

- Accuracy. Tabs fold tight to the edge of the piece and do not drift from left to right.

- Ideal for off line application.

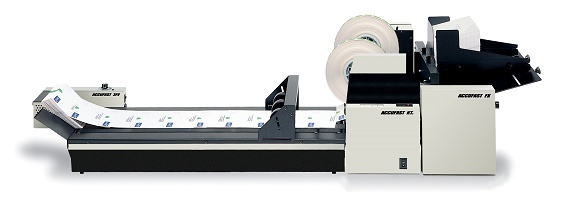

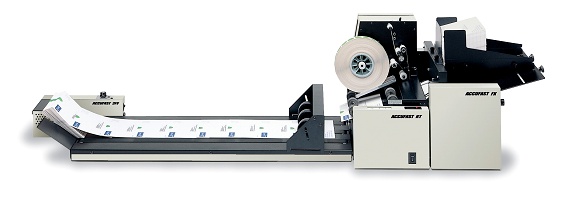

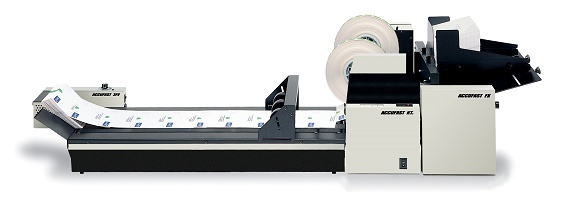

The examples below show different configurations in use with KT and KT2 tabbers.

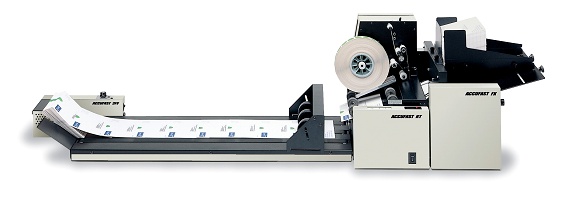

The FX feeder and the 3FV conveyor combine with the KT tabber to make the most reliable single tabbing system going. The FX may also be used in line with a KT2 and features a high speed variant - the FX-03.

The FX feeder and the 3FV conveyor combine with the KT tabber to make the most reliable single tabbing system going. The FX may also be used in line with a KT2 and features a high speed variant - the FX-03.

KT Technical Specifications [top]

- applies 1 tab per piece

- tabs 15,000 pieces per hour

- tabs pieces 5” to 12” wide, from 20 lb. thin to 1/4” thick, coated and uncoated

- runs a variety of 1 and 1.5 inch tabs: paper & clear, circles & rectangles, on rolls with or without tractor holes

- built-in waste take-up spool

- 5,000 one inch and 4,000 1.5 inch tabs per roll.

- weighs 47 pounds

- measures 10”l x 17”h x 21”w

- uses 115 volts 2 amps 60 hz or 230 volts 1 amp 50 hz

- goes in-line with ACCUFAST and other tabletop Labelers, Feeders and Printers

- its outstanding feature is its ability to run both 1 and 1.5 inch tabs at the flick of a switch

KT2 Technical Specifications [top]

- applies 1 or 2 tabs per piece

- tabs 15,000+ pieces per hour

- tabs pieces 5” to 16” wide, from 20 lb. thin to 1/4” thick, coated and uncoated

- runs a variety of 1” tabs: paper & frosted, circles & rectangles, on rolls without tractor holes

- built-in waste take-up spools

- weighs 56 pounds

- measures 11”l x 19”h x 23”w

- uses 115 volts 2 amps 60 hz or 230 volts 1 amp 50 hz

- goes in-line with ACCUFAST and other tabletop Labelers and Printers

- its outstanding feature is a pair of independent tabbing heads – turn them both on to twin tab, turn only one on to single tab

Buy it now

Buy it now